What Is A Hydraulic Accumulator?

A hydraulic accumulator is a pressure storage device that holds hydraulic fluid under pressure, typically using compressible gas like nitrogen. It serves multiple functions within hydraulic systems, such as energy storage, shock absorption, and pressure maintenance.

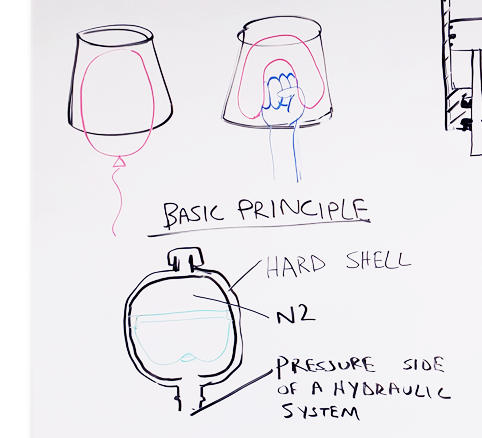

How Does a Hydraulic Accumulator Work?

In hydraulic systems, pulsations often originate from the operation of hydraulic pumps. An accumulator mitigates these pulsations by absorbing pressure fluctuations, thereby stabilizing the system.

A typical accumulator consists of:

- A durable shell, usually made of carbon steel.

- An elastomeric diaphragm or bladder that separates the hydraulic fluid from a pre-charged nitrogen gas chamber.

When the hydraulic system experiences pressure changes, the accumulator responds by compressing or expanding the gas chamber, effectively dampening shocks and maintaining consistent pressure.

Functions of a Hydraulic Accumulator

Hydraulic accumulators perform several critical functions:

- Pulsation Dampening: They absorb pressure spikes and pulsations from pumps, reducing noise and vibration.

- Pressure Maintenance: In the event of minor leaks, accumulators help maintain system pressure until maintenance can be performed.

- Emergency Power Supply: Accumulators can provide immediate hydraulic power during system failures or when rapid response is required, such as in brake systems.

Types of Hydraulic Accumulators

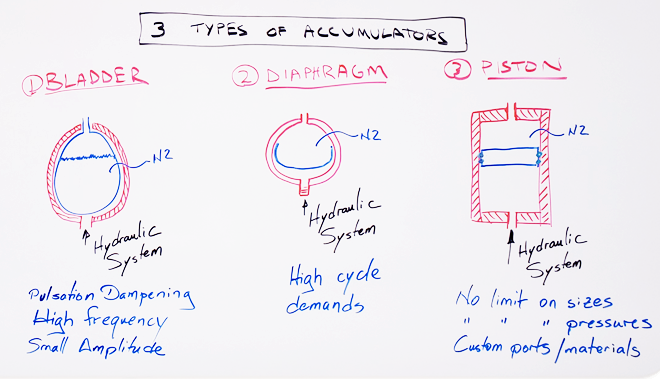

There are three primary types of hydraulic accumulators:

-

Bladder Accumulators

Bladder accumulators feature an internal bladder filled with nitrogen gas. They are widely used due to their rapid response time and effectiveness in absorbing high-frequency, low-amplitude pulsations. However, the vulcanized seam in the bladder can be a point of failure under high-frequency cycling.

-

Diaphragm Accumulators

These accumulators use a diaphragm to separate the gas and fluid chambers. They are suitable for applications requiring high cycle life, as the seamless diaphragm design reduces the risk of failure. Diaphragm accumulators are commonly used in systems with frequent pressure fluctuations.

-

Piston Accumulators

Piston accumulators utilize a piston to separate the gas and fluid. They are highly versatile, accommodating a wide range of pressures and volumes. Their robust design makes them ideal for heavy-duty applications requiring large fluid capacities and high-pressure ratings.

Applications for Hydraulic Accumulators

Hydraulic accumulators are integral to various industries, including:

- Agriculture: Enhancing the performance of equipment like tractors and harvesters.

- Construction: Providing energy storage and shock absorption in machinery such as excavators and loaders.

- Mining: Ensuring consistent hydraulic power in heavy-duty mining equipment.

- Aerospace: Maintaining hydraulic pressure in aircraft systems.